- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

중국 등방성 흑연 제조업체, 공급업체, 공장

- View as

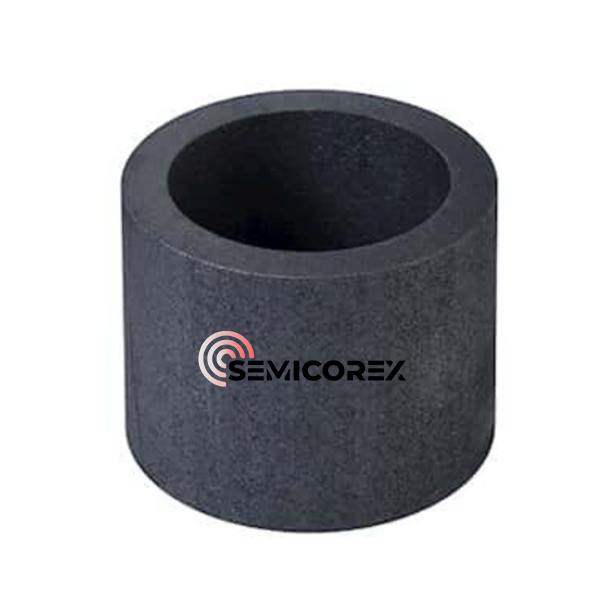

고순도 흑연 도가니

Semicorex 고순도 흑연 도가니의 응용 분야는 반도체 제조부터 금속 주조 및 보석 제조에 이르기까지 다양하며 다양성과 필수성을 보여줍니다.

더 읽어보기문의 보내기흑연 이온 임플란트

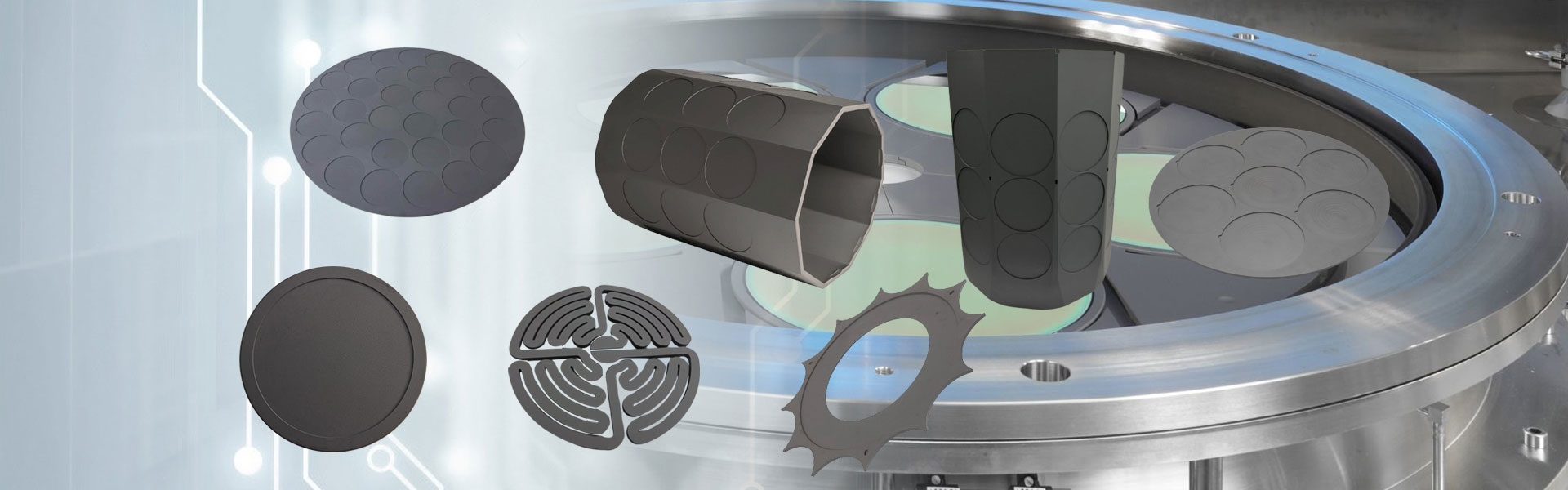

Semicorex Graphite Ion Implanter는 미세 입자 구성, 우수한 전도성 및 극한 조건에 대한 복원력으로 구별되는 반도체 제조 영역에서 중요한 구성 요소입니다.

더 읽어보기문의 보내기

Semicorex는 수년 동안 등방성 흑연을(를) 생산해 왔으며 중국의 전문 등방성 흑연 제조업체 및 공급업체 중 하나입니다. 대량 포장을 제공하는 당사의 고급 내구성 제품을 구매하면 대량의 빠른 배송을 보장합니다. 수년에 걸쳐 우리는 고객에게 맞춤형 서비스를 제공했습니다. 고객은 우리 제품과 우수한 서비스에 만족합니다. 우리는 진심으로 귀하의 신뢰할 수 있는 장기 비즈니스 파트너가 되기를 기대합니다! 우리 공장에서 제품을 구입하는 것을 환영합니다.