- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

중국 알루미나 (Al2O3) 제조업체, 공급업체, 공장

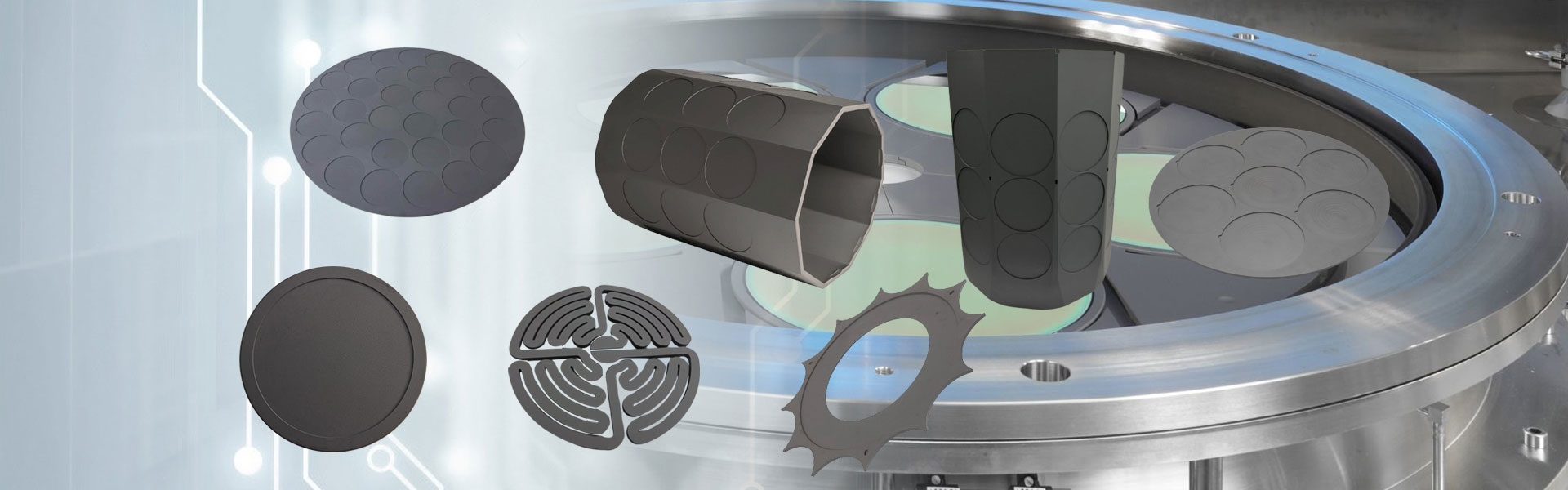

Alumina ceramics are a type of advanced ceramic material that is primarily made of aluminum oxide and the general purpose of ceramists. They are in great demand because of their remarkable comprehensive properties, some of which include high hardness, high wear resistance, and high temperature resistance. These will maintain their structure at very high temperatures. Additionally, alumina ceramics have high electrical insulation and chemical resistance, and very high mechanical strength. While brittleness will limit them. They possess all those properties which has resulted in alumina ceramics playing a central role in the semiconductor industry.

The vacuum chuck will be attached to the vacuum equipment via a connecting pipe. When the chuck comes in contact with the workpiece, i.e., a sheet or film, the vacuum equipment will activate and draw negative pressure in the chuck. The workpiece is carried by atmospheric pressure thus it will cling firmly to the chuck allowing the processing to go on without issue. When the workpiece is done being processed the vacuum machine will stop and the chuck will gradually fill with air. The workpiece will separate of its own accord thus finishing the clamping, processing and handling processes.

Black Alumina ceramic is one of the primary materials used in vacuum chucks. It is primarily composed of Al2O3, with transition metal oxides as colorants and sintering aids added. The process is then sintered at a specific temperature. Vacuum chucks made from porous ceramic feature ultra-fine micrometer-level pores and spacing, enabling reliable handling of thinner and more delicate workpieces. Furthermore, these chucks can accommodate workpieces of varying sizes, eliminating the need to maintain a fixed set of shapes and sizes for each workpiece, thus saving costs and improving efficiency.

Alumina ceramics have a high elastic modulus and specific stiffness, are resistant to deformation, and have a low coefficient of thermal expansion and high thermal stability. They are an excellent structural material and are currently widely used in aviation, aerospace, petrochemicals, machinery manufacturing, the nuclear industry, and microelectronics.

Alumina ceramic components offer excellent properties such as high hardness, high mechanical strength, exceptional wear resistance, high temperature resistance, high resistivity, and excellent electrical insulation. They can meet the complex performance requirements of semiconductor manufacturing in special environments such as vacuum and high temperature. They play an irreplaceable and important role in semiconductor manufacturing production lines, covering nearly all semiconductor manufacturing equipment and serving as key components. Alumina ceramic components are primarily categorized by application, including annular and cylindrical types, airflow guides, load-bearing and fixed types, hand-grip gaskets, and modules.

- View as

다결정 알루미나 섬유판

다결정 알루미나 섬유판은 내열충격성이 우수하고 내식성이 강하며 내산화성이 우수한 고성능 내화판재입니다. 이러한 내화 성능으로 인해 고온 용광로, 고온 가마, 고온 반응기, 고온 파이프라인, 고온 용광로 도어, 고온 용광로 벽을 비롯한 까다로운 고온 환경에서 널리 사용됩니다. Semicorex를 선택하시면 매우 비용 효율적인 가격, 개인화된 일대일 맞춤 서비스 및 탁월한 제품 품질의 혜택을 누리실 수 있습니다.

더 읽어보기문의 보내기맞춤형 세라믹 노즐

세부 사항에 세심한 주의를 기울여 제조된 Semicorex의 맞춤형 세라믹 노즐은 비교할 수 없는 균일성과 정밀도로 가스와 액체의 유량을 제어하기 위한 천재적인 솔루션입니다. 세미코렉스는 여러분의 추가적인 상담을 기대하고 있습니다.

더 읽어보기문의 보내기알루미나 세라믹 조작기

Semicorex 알루미나 세라믹 매니퓰레이터는 고순도 알루미나로 제작된 고성능 반도체 장비 부품으로, 오염 없는 웨이퍼를 정밀하게 처리할 수 있도록 특별히 설계되었습니다. 이 조작기는 뛰어난 청결도, 우수한 안정성, 높은 정밀도, 향상된 효율성 및 신뢰할 수 있는 성능을 갖추고 있어 이상적인 선택이 됩니다.

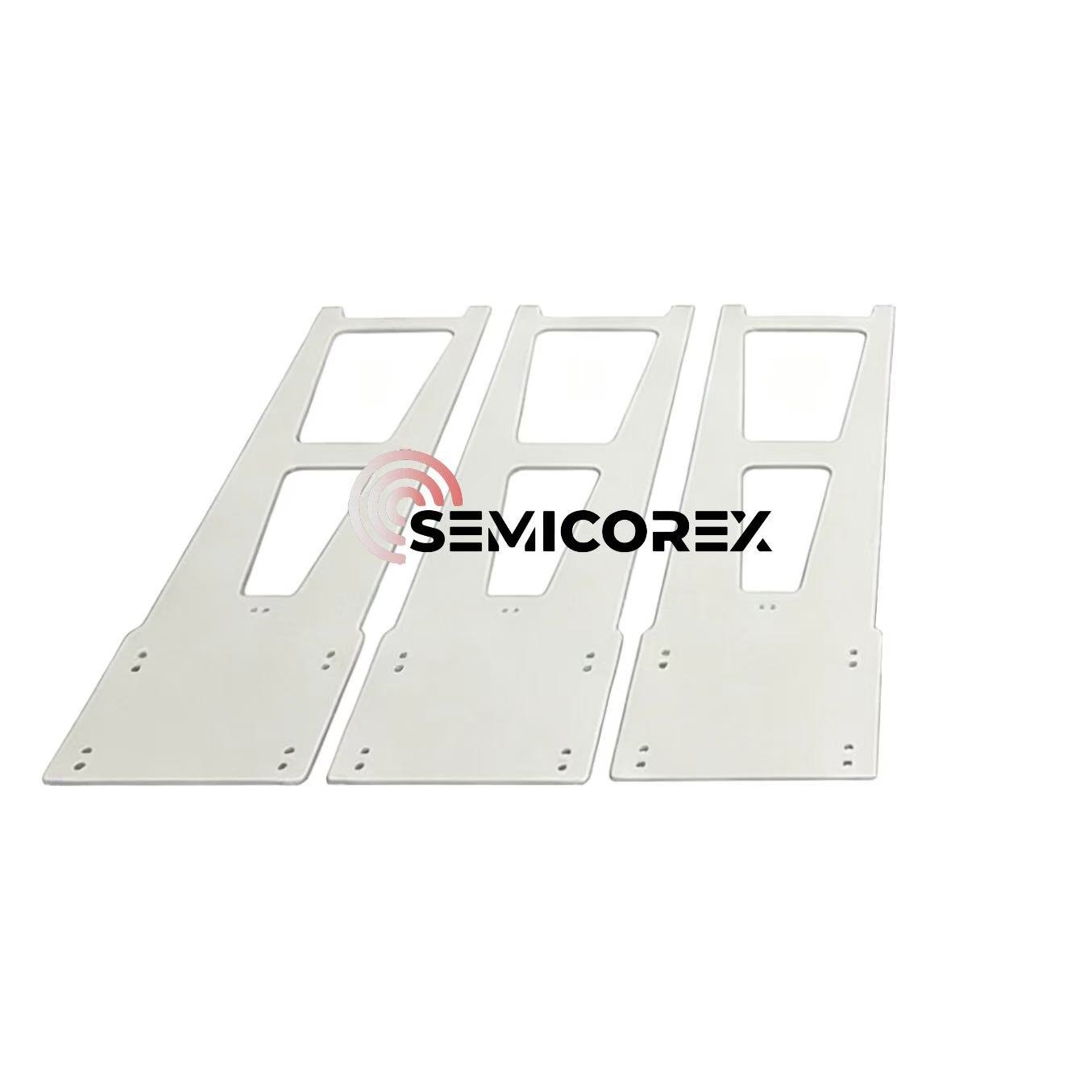

더 읽어보기문의 보내기알루미나 장착베이스 플레이트

Semicorex Alumina 장착베이스 플레이트는 반도체 제조에서 정확한 웨이퍼 처리를 위해 설계된 고성능 세라믹 구성 요소입니다. 우수한 강도, 단열재 및 열 안정성은 클린 룸 자동화 환경을 요구하는 데 이상적입니다.*

더 읽어보기문의 보내기