- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

중국 특수 흑연 제조업체, 공급업체, 공장

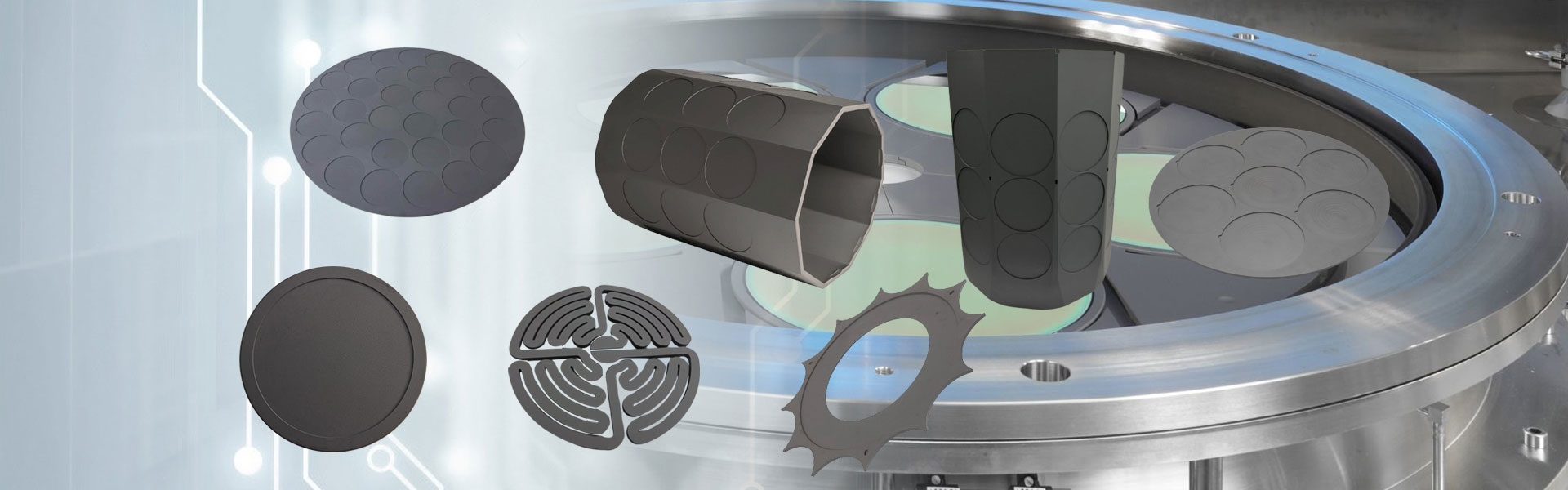

특수 흑연은 처리 된 일종의 인공 흑연입니다. 그것은 결정 성장, 이온 이식, 에피 택시 등을 포함하여 반도체 및 태양 광 제조 공정의 모든 측면에서 없어서는 안될 중요한 재료입니다.

1. 실리콘 카바이드 (SIC) 결정 성장

3 세대 반도체 자료 인 실리콘 카바이드는 새로운 에너지 차량, 5G 통신 및 기타 분야에서 널리 사용됩니다. 6 인치 및 8 인치 SIC 결정 성장 공정에서 등방성 흑연은 주로 다음의 주요 구성 요소를 제조하는 데 사용됩니다.

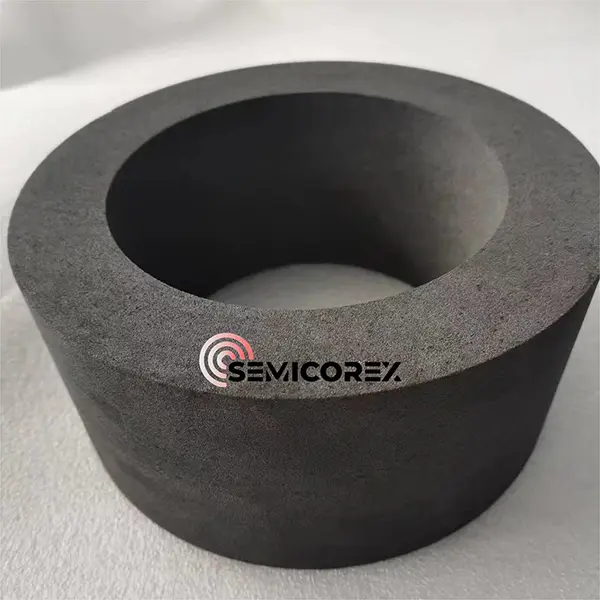

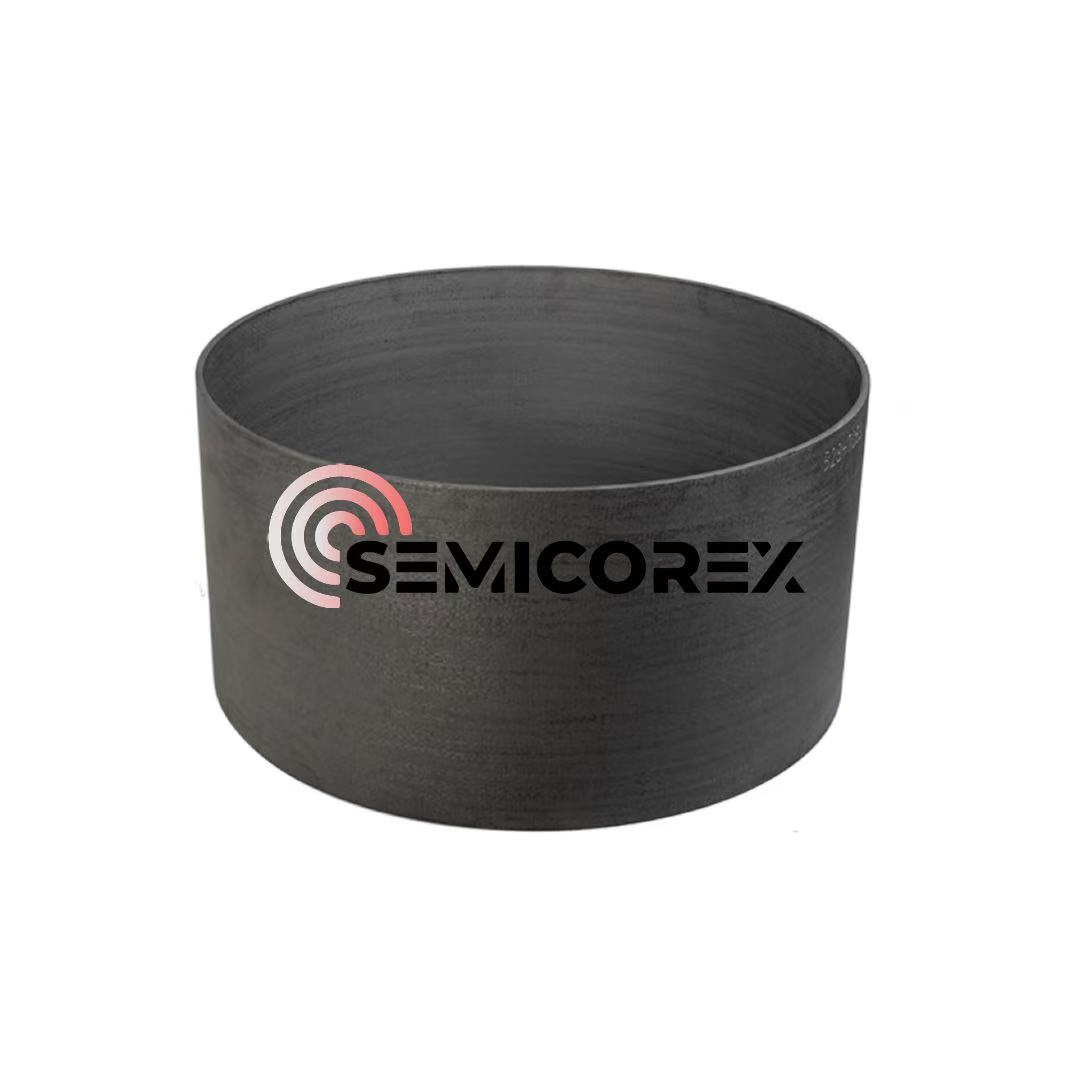

흑연 Crucible : 이것은 SIC 분말 공급 원료를 합성하고 고온에서 결정 성장을 돕는 데 사용될 수 있습니다. 고순도, 고온 저항 및 열 충격 저항은 안정적인 결정 성장 환경을 보장합니다.

흑연 히터 : 이것은 균일 한 열 분포를 제공하여 고품질 SIC 결정 성장을 보장합니다.

절연 튜브 : 이것은 결정 성장 용광로 내에서 온도 균일 성을 유지하고 열 손실을 감소시킵니다.

2. 이온 임플란트

이온 임플란트는 반도체 제조의 핵심 과정입니다. 등방성 흑연은 주로 이온 임플란제에서 다음 성분을 제조하는 데 사용됩니다.

흑연 getter : 이것은 이온 빔에서 불순물 이온을 흡수하여 이온 순도를 보장합니다.

흑연 초점 링 : 이것은 이온 빔에 초점을 두어 이온 임플란트 정확도와 효율성을 향상시킵니다. 흑연 기질 트레이 : 실리콘 웨이퍼를지지하고 이온 임플란트 동안 안정성과 일관성을 유지하는 데 사용됩니다.

3. 에피 택시 과정

에피 택시 프로세스는 반도체 장치 제조의 중요한 단계입니다. 등방성 프레스 흑연은 주로 에피 택시 용광로에서 다음 성분을 제조하는 데 주로 사용됩니다.

흑연 트레이 및 감수자 : 실리콘 웨이퍼를지지하는 데 사용되어 에피 택시 과정에서 안정적인지지 및 균일 한 열 전도를 제공합니다.

4. 기타 반도체 제조 응용 분야

등방성 프레스 흑연도 다음과 같은 반도체 제조 응용 분야에서 널리 사용됩니다.

에칭 공정 : 에칭을위한 흑연 전극 및 보호 성분을 제조하는 데 사용됩니다. 부식 저항과 고순도는 에칭 과정에서 안정성과 정밀도를 보장합니다.

화학 증기 증착 (CVD) : CVD 용광로 내에서 흑연 트레이 및 히터를 제조하는 데 사용됩니다. 높은 열전도율과 고온 저항은 균일 한 박막 증착을 보장합니다.

포장 테스트 : 테스트 비품 및 캐리어 트레이를 제조하는 데 사용됩니다. 높은 정밀도와 낮은 오염은 정확한 테스트 결과를 보장합니다.

흑연 부품의 장점

고순도 :

불순물 함량이 매우 낮은 고순도로 눌린 흑연 물질을 사용하여 반도체 제조의 엄격한 재료 순도 요구 사항을 충족합니다. 회사 자체 정제 용광로는 흑연을 5ppm 미만으로 정화 할 수 있습니다.

높은 정밀도 :

고급 처리 장비 및 성숙한 처리 기술을 통해 제품의 차원 정확도와 형태 및 위치 공차가 미크론 수준에 도달하도록합니다.

고성능 :

이 제품은 우수한 고온 저항, 부식성, 방사선 저항, 높은 열전도율 및 기타 특성을 가지며 반도체 제조의 다양한 가혹한 작업 조건을 충족합니다.

맞춤형 서비스 :

다양한 응용 프로그램 시나리오의 요구를 충족시키기 위해 고객 요구에 따라 맞춤형 제품 설계 및 처리 서비스를 제공 할 수 있습니다.

흑연 제품의 유형

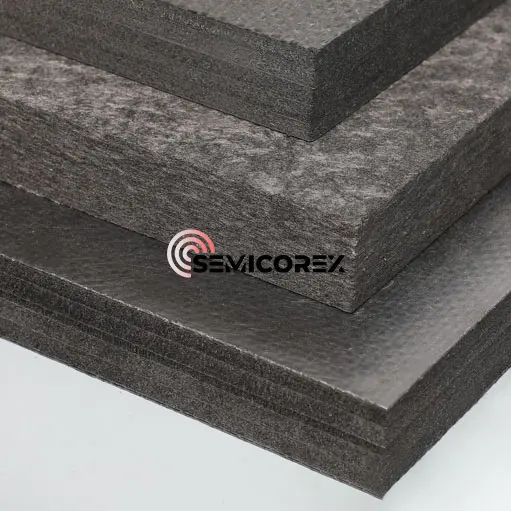

(1) 등방성 흑연

등방성 흑연 생성물은 콜드 등방성 프레스에 의해 생산됩니다. 다른 형성 방법과 비교하여,이 과정에 의해 생성 된 도가킬은 우수한 안정성을 갖는다. SIC 단일 결정에 필요한 흑연 생성물의 크기는 크기가 크며, 이는 표면과 흑연 제품 내부의 고르지 않은 순도로 이어질 것이며, 사용 요구 사항을 충족시킬 수 없습니다. SIC 단결정에 필요한 대형 흑연 생성물의 깊은 정제 요구 사항을 충족시키기 위해, 대형 크기 또는 특수 형 흑연 생성물의 깊고 균일 한 정제를 달성하기 위해 독특한 고온 열 화학적 펄스 정제 공정을 채택하여 제품 표면 및 코어의 순도가 사용 요구 사항을 충족시킬 수 있도록해야합니다.

(2) 다공성 흑연

다공성 흑연은 다공성이 높고 밀도가 낮은 흑연의 한 유형입니다. SIC 결정 성장 과정에서, 다공성 흑연은 질량 전달 균일 성을 개선하여 상 변화의 발생률을 감소시키고 결정 모양을 향상시키는 데 중요한 역할을한다.

다공성 흑연의 사용은 원료 영역의 온도 및 온도 균일 성을 개선하고 도가니의 축 온도 차이를 증가 시키며, 원료 표면의 재결정 화을 약화시키는 데 특정 영향을 미칩니다. 성장 챔버에서, 다공성 흑연은 성장 과정 전체에 걸쳐 재료 흐름의 안정성을 개선하고, 성장 영역의 C/SI 비율을 증가시키고, 상 변화의 확률을 줄이는 데 도움이되며, 다공성 흑연은 또한 결정 인터페이스를 개선하는 데 중요한 역할을한다.

(3) 펠트

Soft Felt and Hard는 SIC 결정 성장 및 에피 택셜 링크에서 중요한 열 단열재의 역할을합니다.

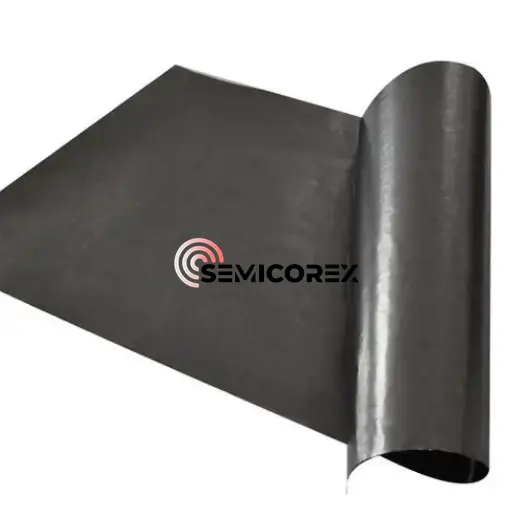

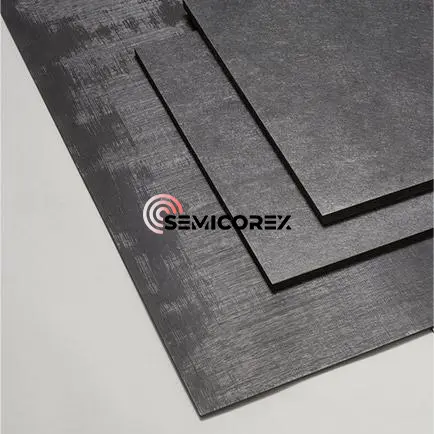

(4) 흑연 포일

흑연 종이는 화학 처리 및 고온 롤링을 통해 고 탄소 플레이크 흑연으로 만든 기능적 물질입니다. 열전도율이 높고 전기 전도도, 유연성 및 부식 저항이 있습니다.

(5) 복합 재료

탄소 탄소 열전대는 태양 광 단결정 용광로 생산의 핵심 소모품 중 하나입니다.

반음 생산

Semicorex는 소규모 배치, 맞춤형 생산 방법으로 흑연을 만듭니다. 소규모 배치 생산으로 제품을 더욱 제어 할 수 있습니다. 전체 프로세스는 PLC (Programmable Logic Controllers)에 의해 제어되며, 상세한 프로세스 데이터가 기록되어 완전한 수명주기 추적 성이 가능합니다.

전체 로스팅 과정에서, 다른 위치에 걸쳐 저항성에서 일관성이 달성되었으며, 단단한 온도 제어가 유지되었습니다. 이것은 흑연 물질의 균질성과 신뢰성을 보장합니다.

Semicorex는 다른 공급 업체와 다른 완전 등방성 프레스 기술을 사용합니다. 이는 흑연이 매우 균일 한 자체이며 에피 탁상 과정에서 특히 중요하다는 것을 의미합니다. 밀도, 저항력, 경도, 굽힘 강도 및 다양한 샘플의 강도를 포함한 포괄적 인 재료 균일성 테스트가 수행되었습니다.

- View as

SiC 코팅 흑연 도가니

SiC 코팅 흑연 도가니는 탄화규소 코팅 흑연 소재를 정밀 가공한 필수 용기로, 뛰어난 내열성과 화학적 내식성을 제공합니다. 우수한 성능과 신뢰할 수 있는 품질을 갖춘 Semicorex의 SiC 코팅 흑연 도가니는 제어된 고품질 결정 생산을 달성하기 위한 최적의 솔루션입니다.

더 읽어보기문의 보내기C/C 단열 실린더

C/C 단열 실린더는 단결정 실리콘 성장을 위한 열장 시스템에 사용되는 고성능 단열 부품으로 단열 및 지지 기능을 모두 수행합니다. 뛰어난 단열 성능, 우수한 구조 강도 및 경쟁력 있는 가격을 갖춘 Semicorex C/C 단열 실린더는 고품질 결정 성장 공정에 이상적인 옵션입니다.

더 읽어보기문의 보내기C/C 복합 도가니 홀더

Semicorex C/C 복합 도가니 홀더는 정밀하게 제조된 탄소-탄소 복합 부품으로, 고온 조건의 엄격한 요구 사항을 충족하도록 특별히 맞춤 제작되었습니다. 이는 일반적으로 도가니 바닥에 위치하며 고온 결정 성장로에서 도가니를 안정화하기 위한 신뢰할 수 있는 지원 솔루션입니다.

더 읽어보기문의 보내기탄소-탄소 복합 흐름 가이드

탄소-탄소 복합 흐름 가이드는 고급 원통형 반도체 부품으로, 고온 풀링 시스템에서 단결정 실리콘의 성공적인 제조를 보장하는 뛰어난 솔루션 역할을 합니다. 이는 고온 단결정 실리콘 생산 중에 가스 흐름 디렉터와 단열재 역할을 모두 수행할 수 있습니다.

더 읽어보기문의 보내기