- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

중국 알루미나 (Al2O3) 제조업체, 공급업체, 공장

- View as

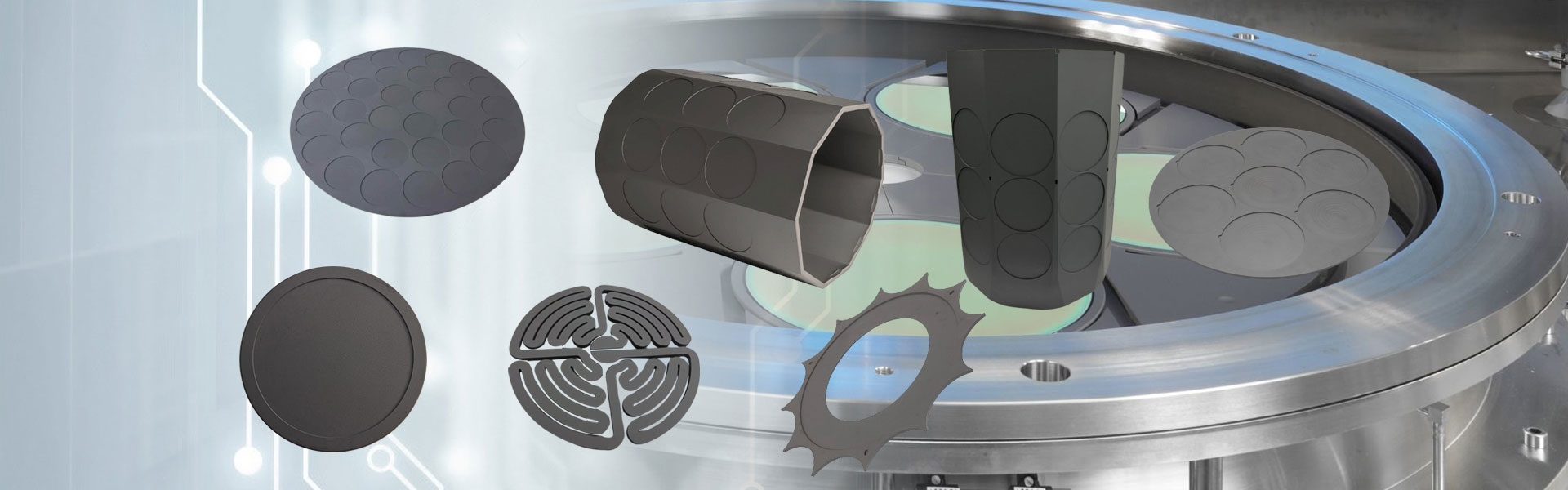

알루미나 엔드 이펙터

Semicorex Alumina End Effector는 미세한 결함조차도 장치 성능을 저하시킬 수 있는 까다로운 반도체 제조 영역에서 없어서는 안 될 도구로 등장했으며, 정밀 웨이퍼 핸들링의 역할은 아무리 강조해도 지나치지 않습니다. 알루미나 엔드 이펙터는 다양한 제조 공정 전반에 걸쳐 섬세한 실리콘 웨이퍼를 조작하는 데 필수적인 정밀도, 순도 및 내구성의 고유한 조합을 제공합니다.**

더 읽어보기문의 보내기알루미나 세라믹 로봇 팔

웨이퍼 핸들링 세라믹 로봇 암 또는 세라믹 실리콘 웨이퍼 핸들링 포크라고도 알려진 Semicorex 알루미나 세라믹 로봇 암은 고성능 반도체 장비 부품입니다. 이 제품은 반도체 제조의 엄격한 요구 사항을 고려하여 설계되었습니다. 높은 내열성, 내마모성, 화학적 안정성 및 우수한 전기 절연 특성을 갖춘 알루미나 세라믹 암은 글로벌 반도체 제조 산업에서 대체할 수 없는 역할을 합니다. Semicorex는 품질과 비용 효율성을 융합한 고성능 알루미나 세라믹 로봇 팔을 제조 및 공급하는 데 전념하고 있습니다.**

더 읽어보기문의 보내기알루미나 세라믹 플랜지

알루미나 세라믹 플랜지는 특히 열 안정성, 중량 고려 사항 및 내식성이 가장 중요한 환경에서 상당한 이점을 제공하는 엔지니어링 부품입니다. 이러한 플랜지는 내구성과 신뢰성이 있을 뿐만 아니라 사용되는 시스템의 전반적인 효율성과 비용 효율성에도 기여합니다. 고유한 특성으로 인해 다양한 산업 분야의 고급 엔지니어링 솔루션을 위한 탁월한 선택이 됩니다. Semicorex는 품질과 비용 효율성을 융합한 고성능 알루미나 세라믹 플랜지를 제조 및 공급하는 데 전념하고 있습니다.**

더 읽어보기문의 보내기알루미나 세라믹 웨이퍼 척

Semicorex 알루미나 세라믹 웨이퍼 척은 단일 산업에만 국한되지 않습니다. 고유한 특성으로 인해 광범위한 응용 분야에 적합합니다. 반도체 부문에서는 칩 제조 중에 웨이퍼를 고정하는 데 사용됩니다. 화학 산업에서는 내식성이 뛰어나 공격적인 물질을 처리하는 데 이상적입니다. 환경 응용 분야에서는 안정성과 내마모성이라는 이점을 누리는 동시에 기계적 특성을 기능성 소재 개발에 활용합니다. Semicorex는 품질과 비용 효율성을 융합한 고성능 알루미나 세라믹 웨이퍼 척을 제조 및 공급하는 데 전념하고 있습니다.

더 읽어보기문의 보내기