- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

중국 등방성 흑연 제조업체, 공급업체, 공장

- View as

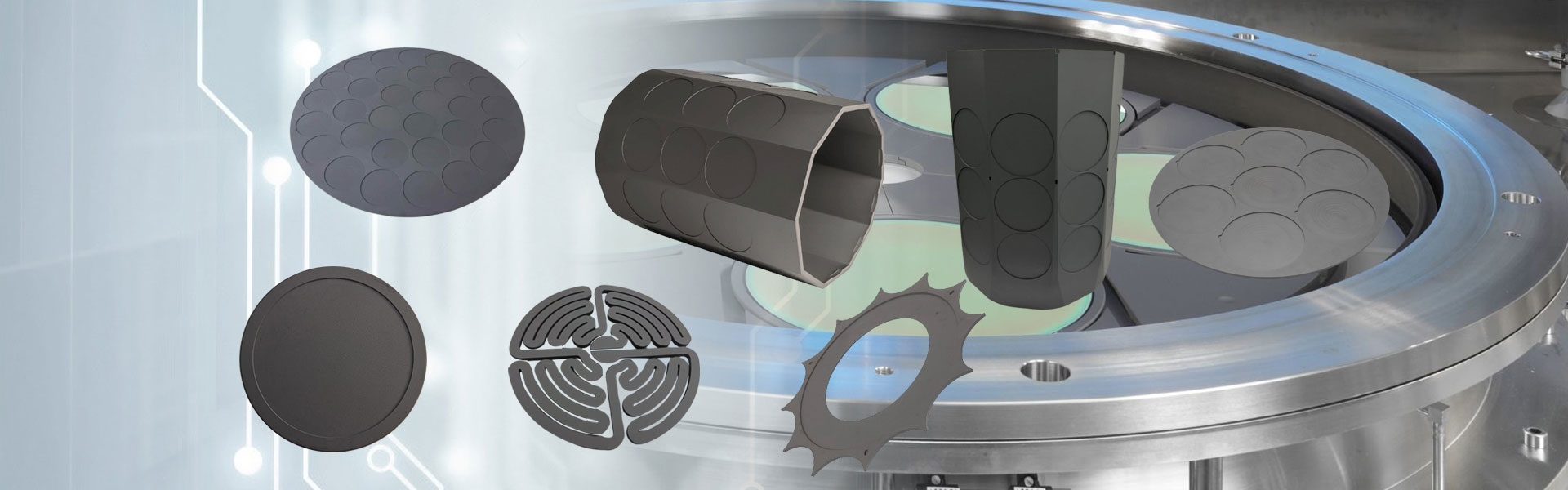

흑연 슬라이드 플레이트

세미코렉스의 흑연 슬라이드 플레이트는 자가 윤활 기능을 갖추고 있어 기계적 주행 저항을 효과적으로 줄이고, 작동 효율성을 향상시키며, 윤활 부족 또는 윤활 불량으로 인한 기계적 고장을 최소화할 수 있습니다.

더 읽어보기문의 보내기

Semicorex는 수년 동안 등방성 흑연을(를) 생산해 왔으며 중국의 전문 등방성 흑연 제조업체 및 공급업체 중 하나입니다. 대량 포장을 제공하는 당사의 고급 내구성 제품을 구매하면 대량의 빠른 배송을 보장합니다. 수년에 걸쳐 우리는 고객에게 맞춤형 서비스를 제공했습니다. 고객은 우리 제품과 우수한 서비스에 만족합니다. 우리는 진심으로 귀하의 신뢰할 수 있는 장기 비즈니스 파트너가 되기를 기대합니다! 우리 공장에서 제품을 구입하는 것을 환영합니다.